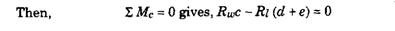

Bearing Loads on the Front Axle

Bearing Loads on the Front Axle Figure 27.6 illustrates the forces and the reactions on steering knuckle when the vehicle is at rest. The thrust load and the knuckle-pin-bearing load can be expressed in terms of the reaction of wheel on wheel spindle. Let, Rw = The reaction of the wheel on the spindle acting vertically through the centre of contact of tyre on ground. Rt = The load on the thrust bearing Ru = The load on the upper knucklepin bearing Rl = The load on lower knucklepin 'B' and 'C represent the centres of lower and upper knuckle-pin bearings respectively. 'A' is a point on the spindle axis in the centre plane of the wheel. Fig. 27.6. Forces and reaction on steering knuckle. The other loads acting on knuckle-pin bearing are those due to the rolling resistance and road shocks. These loads are proportional to the static load and hence can be accounted for.