Crown Wheel Adjustment

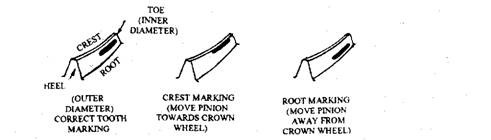

Crown Wheel Adjustment After setting the pinion, the crown wheel is installed in the assembly. The correct bearing cap must be used during this operation, as these are not interchangeable. Backlash is adjusted at this stage by moving the crown wheel towards or away from the pinion. Prior to the final measurement of backlash with a clock gauge, it is necessary to ensure that the crown wheel run-out is within the recommended limits. Meshing of the gear is checked by applying a smear of marking compound to the driving side of a few crown wheel teeth and then turning the pinion in the direction of rotation while applying a resistance to the crown wheel. The marking thus obtained indicates the mesh of the gears with respect to pinion position and backlash. Figure 26.41 illustrates the change, in relation to the correct marking, when the pinion position is changed. A 'correct' marking indicates only a limited contact between the teeth under light-load test conditions. But if full lo