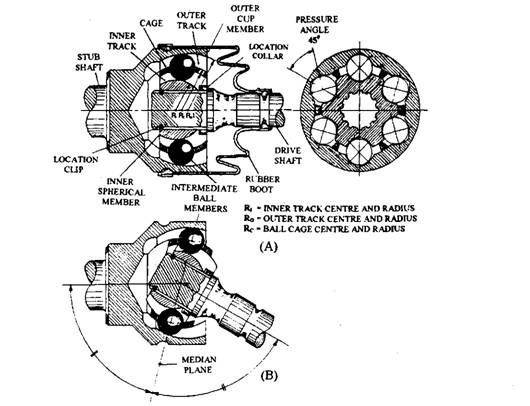

Birfield Joint

The Birfield joint, manufactured by Hardy Spicer Limited , is based on the Rzeppa principle (Fig. 26.17). In this construction the joint's performance has been improved further by incorporating converging ball tracks, which do not rely on a controlled ball cage to maintain the intermediate ball members on the median plane (Fig. 26.17B). This Joint uses an inner (ball) input member driving an outer (cup) member. Torque is transmitted from the input to the output member again by six intermediate ball members, which fit into curved rack grooves formed in both the cup and spherical members. Articulation of the joint takes place due to rolling of the balls in between the inner and outer pairs of curved grooves. Constant velocity conditions are achieved by an intermediate member, formed by a ring of six balls placed in the median plane (Fig. 26.17B) of the shape of the curved ball tracks generated in both the input and output joint members. Fig. 26.17. Birfield. Rzeppa type consta