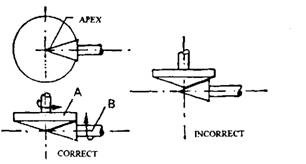

Rzeppa Joint

A Ford engineer, Alfred Hans Rzeppa (pronounced sheppa) invented one of the first practical constant velocity joints in 1926. This joint was able to transmit torque over a wide range of angles. An improved version of the joint was patented by Rzeppa in 1935. This version uses six balls as intermediate members, which are kept at all times in a plane bisecting the angle between the input and output shafts (Fig. 26.16). A controlled guide ball cage is incorporated, which maintains the balls in the bisecting plane (or the median plane) by means of a pivoting control strut, which swivels the cage at the correct angle. This control strut is located in the centre of the enclosed end of the outer cup member. Both ball ends of the strut are positioned in a recess and socket formed in the adjacent ends of the driving and driven members of the joint respectively. A large spherical waist approximately midway along the strut aligns with a hole made in the centre of the cage. Any angular inclinati