Braking Fundamentals

Braking Fundamentals

Energy of Motion.

Kinetic energy is the force that keeps the vehicle moving. This energy is provided by the engine in order to accelerate the vehicle from a standstill to desired speed. Kinetic energy is dissipated as heat by the brakes during application of breaks (Fig. 28.1). The kinetic energy of a vehicle during braking is given by

Thus, the kinetic energy doubles as the weight doubles, but it increases four times as speed doubles.

Fig. 28.1. Illustration of braking.

Coefficient of Friction.

Frictional force opposes the motion of the vehicle. Consequently it consumes power and produces heat. Frictional force occurs between the sliding tire and the road surface when wheel rotation is locked by brakes. The ability of a vehicle to stop depends on the coefficient of friction between the contacting surfaces. Maximum useable coefficient of friction occurs between the tyre and road surface. Passenger car brakes have coefficient of friction 0.3 to 0.5.

The amount of energy that can be absorbed by the brakes depends upon the coefficient of friction of the brake materials, brake diameter, brake surface area, shoe geometry, and the pressure used to actuate the brake. Stopping a car suddenly means very high friction, resulting in high brake temperature.

28.1.1.

The amount of energy that can be absorbed by the brakes depends upon the coefficient of friction of the brake materials, brake diameter, brake surface area, shoe geometry, and the pressure used to actuate the brake. Stopping a car suddenly means very high friction, resulting in high brake temperature.

28.1.1.

Brake Balance

The braking of a vehicle occurs at ground level, so affective braking force acts on the ground. Vehicle weight and kinetic energy of the vehicle act through center of gravity, which are above ground level. This causes the vehicle to pitch forward as the brakes are applied. As a result of this action some of the vehicle weight is effectively transferred from the rear wheels to the front wheels. Consequently, the front brakes must absorb more kinetic energy than the rear brakes. The maximum transfer of weight amounts to

This weight is added to the static weight on the front wheels and subtracted from the static weight on the rear wheels. The front wheel static weight is normally 55% of the vehicle weight. Front brakes are designed to absorb this extra brake effort by selecting shoe-drum or shoe-disc

combination type, brake size, lining coefficient of friction, wheel cylinder size and differential hydraulic actuating pressures. With full braking it is desirable to have the front brakes lock up slightly ahead of the rear brakes. This causes the car to go straight ahead and to not spin out.

Example 28.1. A vehicle has its wheel base equal to 3 times the height of its CG above the ground. If the vehicle is braked on all four wheels over a road whose adhesion factor is 0.6, determine the weight transferred from the rear to front wheels.

combination type, brake size, lining coefficient of friction, wheel cylinder size and differential hydraulic actuating pressures. With full braking it is desirable to have the front brakes lock up slightly ahead of the rear brakes. This causes the car to go straight ahead and to not spin out.

Example 28.1. A vehicle has its wheel base equal to 3 times the height of its CG above the ground. If the vehicle is braked on all four wheels over a road whose adhesion factor is 0.6, determine the weight transferred from the rear to front wheels.

28.1.2.

Stopping Distance

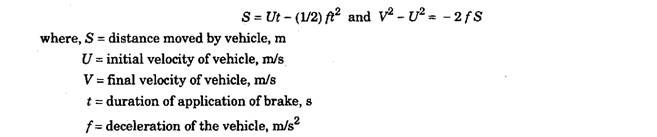

Stopping distance is extremely important for emergency braking. The stopping distance is 1 based on the deceleration rate. Also, it is affected by the tyre deflection, air resistance, braking efforts and the inertia of the driveline. Distance travelled by the vehicle during application of brake can be obtained from the following equations of motion assuming the brake efficiency as 100%.

If the vehicle comes to stand still due to application of brake, the final velocity, V = 0 in the above equations, then stopping distance, S is given by the relations, S = U /2f.

The stopping distance remains same with the same tyre and road conditions, when the wheels are locked and skidding, regardless of the weight, number of wheels or vehicle load. Maximum braking force occurs when the wheels are braked just before the locking point or point of impending skid. Non-skid brake systems are designed to operate at or below this point. Any changes in load on a wheel changes the point of impending skid.

Example 28.2. Calculate the minimum stopping distances for a vehicle travelling at 60 kmlhr with a deceleration equal to the acceleration due to gravity.

The stopping distance remains same with the same tyre and road conditions, when the wheels are locked and skidding, regardless of the weight, number of wheels or vehicle load. Maximum braking force occurs when the wheels are braked just before the locking point or point of impending skid. Non-skid brake systems are designed to operate at or below this point. Any changes in load on a wheel changes the point of impending skid.

Example 28.2. Calculate the minimum stopping distances for a vehicle travelling at 60 kmlhr with a deceleration equal to the acceleration due to gravity.

28.1.3.

Brake Fade

Since brake lining material is a poor conductor of heat, most of the heat goes into the brake drum or disc during braking. Under severe use, brake drums may reach 590 K temperatures. The coefficient of friction between the drum and lining is much lower at these high temperatures so that additional pedal pressure is required. After a number of severe stops or after holding the brakes on a long down hill grade, a point is eventually reached when the coefficient of friction drops so low that little braking effect is available. This condition is called brake fade.

In drum brakes, the lining covers a large portion of the internal drum surface so that a little cooling space is available. Therefore, drum brakes are more susceptible to fade than disc brakes. As the vehicle moves, cooling air is directed around the drum and disc to remove brake heat. The maximum brake torque that can be absorbed by the lining or pad depends on the size and type of brake, gross vehicle weight, axle loading, the front to rear braking ratio and maximum attainable speed.

The drum and disc expansion due to brake temperature is another factor for brake fade. The diameter of the drum increases as it gets hot. The shoe no longer matches the drum and hence lining-to-drum contact surface becomes smaller. The same stopping force requires higher pedal pressure and this is turn increases the temperature on the smaller contact surface. Continued braking increases the problem until the braking becomes ineffective, regardless of the pedal force. On the other hand, expansion of disc has little effect on braking because the pads apply braking force on the side of the disc and hence braking surface area remains constant. Leading shoes are more susceptible to fade than trailing shoes.

Fade-resistant drum brakes must limit brake shoe arc to 110 degrees and power absorption

to 28370 kW/m* of lining. The power absorbed by the brakes during a stop can be calculated as,

In drum brakes, the lining covers a large portion of the internal drum surface so that a little cooling space is available. Therefore, drum brakes are more susceptible to fade than disc brakes. As the vehicle moves, cooling air is directed around the drum and disc to remove brake heat. The maximum brake torque that can be absorbed by the lining or pad depends on the size and type of brake, gross vehicle weight, axle loading, the front to rear braking ratio and maximum attainable speed.

The drum and disc expansion due to brake temperature is another factor for brake fade. The diameter of the drum increases as it gets hot. The shoe no longer matches the drum and hence lining-to-drum contact surface becomes smaller. The same stopping force requires higher pedal pressure and this is turn increases the temperature on the smaller contact surface. Continued braking increases the problem until the braking becomes ineffective, regardless of the pedal force. On the other hand, expansion of disc has little effect on braking because the pads apply braking force on the side of the disc and hence braking surface area remains constant. Leading shoes are more susceptible to fade than trailing shoes.

Fade-resistant drum brakes must limit brake shoe arc to 110 degrees and power absorption

to 28370 kW/m* of lining. The power absorbed by the brakes during a stop can be calculated as,

Brake Torque.

The braking torque is the twisting action caused by the drum or disc on the shoes or caliper anchors during the application of brakes. The amount of torque is determined by the effective axle height and stopping force between the tyre and road surface.

Brake torque on the front wheels is absorbed by the knuckle and suspension control arm. In rear, it is absorbed by the axle housing and the leaf spring or control arm. Braking torque during an emergency stop is much higher than accelerating torque at full throttle. Brake supporting and anchoring members must, therefore, have sufficient strength to withstand these high braking loads.

Brake torque on the front wheels is absorbed by the knuckle and suspension control arm. In rear, it is absorbed by the axle housing and the leaf spring or control arm. Braking torque during an emergency stop is much higher than accelerating torque at full throttle. Brake supporting and anchoring members must, therefore, have sufficient strength to withstand these high braking loads.

Brake Safety.

All automobiles are equipped with an emergency brake that would operate independently from the service brakes. Safety standard require the emergency brake to hold the automobile on a 30% slope indefinitely after the brake has been applied until the operator releases it.

28.1.4.

28.1.4.

Work Done in Braking

The kinetic energy possessed by a moving vehicle depends on the weight and speed of the vehicle. This energy must be partially or totally dissipated when the vehicle is slowed down or brought to a standstill. The brake converts the kinetic energy possessed by the vehicle at any one time into heat energy by means of friction.

Example 28.3. A car of mass 800 kg is travelling at 36 kmph. Determine (a) the kinetic energy it possesses, and

(6) the average braking force to bring it to rest in 20 meters.

(6) the average braking force to bring it to rest in 20 meters.

28.1.5.

Braking Efficiency

The force applied during braking of a vehicle opposes the motion of the wheels, as a result reduces the vehicle speed or brings it to a standstill. Therefore the braking force is the force of resistance applied to stop a vehicle or reduce its speed. The braking efficiency of a vehicle is defined as the braking force produced as a percentage of the total weight of the vehicle. Thus,

The braking efficiency is generally less than 100% because of insufficient road adhesion, the vehicle is on a down gradient or ineffective brake system. The brake efficiency is similar to the coefficient of friction, which is the ratio of the frictional force to the normal load between the rubbing surfaces.

Example 28.4. Determine the braking efficiency of a vehicle if the brakes bring the vehicle to rest from 60 kmph in a distance of 15 meters.

28.1.6.

Comments

Post a Comment